🎉 Trainday now integrates with Zendesk and Hubspot 🎉 Trainday now integrates with Zendesk and Hubspot 🎉 Trainday now integrates with Zendesk and Hubspot

🎉 Trainday now integrates with Zendesk and Hubspot

🎉 Trainday now integrates with Zendesk and Hubspot

Contact

Machining Safety: How Data Transforms Training Practices in the Manufacturing Sector

In the manufacturing sector, particularly in machining operations, the integration of data into training practices is revolutionizing safety protocols. "Machining Safety" examines how manufacturers are leveraging data from various sources to significantly enhance the effectiveness and relevance of safety training for machine operators. This blog post explores the transformative impact of data-driven strategies in developing training programs that not only reduce workplace accidents but also foster a proactive safety culture within manufacturing environments.

Utilizing Data to Pinpoint Safety Challenges

Effective safety training in machining operations starts with a detailed analysis of existing risks, which can be identified through comprehensive data collection.

Analyzing Incident and Accident Reports

Thorough reviews of incident and accident reports provide critical insights into common hazards associated with machining operations. This data helps identify the most frequent and severe risks, enabling companies to focus their training efforts on mitigating these specific dangers.

Worker Feedback and Performance Metrics

Incorporating feedback from machine operators offers an additional layer of data that is essential for tailoring training programs. Operators can provide firsthand insights into the everyday risks they face, which might not be fully captured through formal reporting channels. Performance metrics further illuminate areas where safety training could be enhanced to prevent operational errors and accidents.

Developing Focused Training Modules

Armed with precise information on safety risks, manufacturers can create targeted training modules that specifically address the identified challenges.

Scenario-Based Safety Drills

Creating training scenarios that reflect the real-life situations machine operators encounter allows for practical, hands-on learning. These scenarios are designed to simulate common operational challenges and emergencies, providing workers with the skills to manage risks effectively and safely.

Specialized Skill Enhancement

Data analysis often reveals specific skills that need improvement to bolster safety. For instance, if data shows a high rate of accidents related to improper machine setup, specialized training can be developed focusing on correct setup procedures, routine maintenance, and safety checks.

Continuous Improvement Through Data Integration

A dynamic approach to safety training, supported by ongoing data collection and analysis, ensures that training programs are continuously refined to adapt to new technologies and operational changes.

Regular Updates and Adaptations

As machining technologies evolve and new types of machinery are introduced, safety training must also be updated. Regularly integrating new data into training programs ensures that they remain current and effective, covering the latest safety standards and machine operation protocols.

Proactive Risk Management

Utilizing data for predictive analytics allows manufacturers to foresee potential future risks and integrate preventive measures into training programs. This proactive approach not only prevents accidents but also enhances the overall safety culture by encouraging continuous vigilance and safety awareness among workers.

Enhancing Compliance and Documentation

Data-driven training programs not only improve safety outcomes but also ensure compliance with industry regulations and facilitate thorough documentation.

Regulatory Compliance

Ensuring that training programs are compliant with industry safety standards is essential. Data-driven insights help align training with regulatory requirements, thereby minimizing legal risks and ensuring operational compliance.

Detailed Record-Keeping

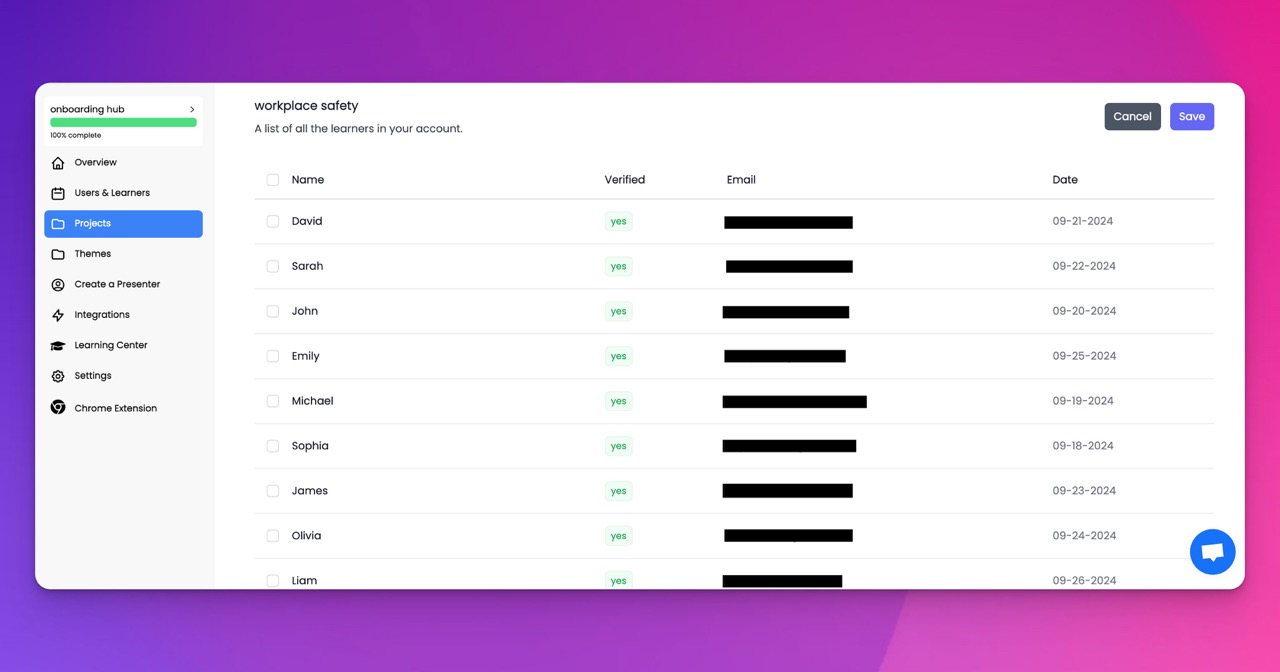

Effective data management enhances the ability to maintain detailed records of training sessions, certifications, and safety audits. These records are crucial for demonstrating compliance during inspections and provide evidence of the company’s commitment to maintaining high safety standards.

Conclusion

"Machining Safety: How Data Transforms Training Practices in the Manufacturing Sector" highlights the critical role of data in enhancing safety training for machining operations. By leveraging detailed analytics to tailor training initiatives, manufacturers can significantly reduce risks and create safer work environments. This approach not only protects employees but also boosts overall productivity and operational efficiency, establishing a robust foundation for safety and excellence in the manufacturing industry.

Accelerate Compliance.

Deliver OSHA-Ready Courses Instantly.

Empower your team with data-driven training solutions tailored to your industry's safety standards. Stay compliant, reduce risks, and boost productivity with AI-powered course creation.